While thinking about how to upgrade my Delta printer, I was considering the viability of using ball screws instead of pulleys and belts. However since the movement of the carriages is sometimes 4 times greater that the actual speed of the print head, this seems like a bad idea.

That lead me down onto a path of comparing the existing printer designs.

With a cross axis design, we would only need one ball screw per axis. With the rigidity we gain from the ball screws we could probably get away with not using a bowden extruder.

That leaves just calculating if we can get cheap enough ball screws and if a normal NEMA17 can drive them fast enough...

That lead me down onto a path of comparing the existing printer designs.

- Cartesian: The classic, but moving the bed just creates unnecessary acceleration artifacts.

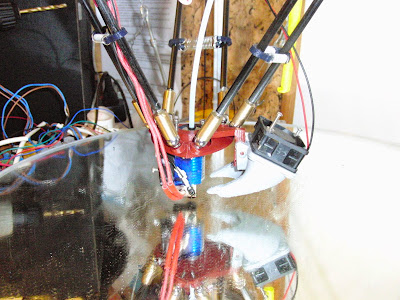

- Delta: Looks good, but the aforementioned speed issue, salmon skin/moire and the extra z height cause some issues

- CoreXY: The underdog, seemingly combines the best from the previous designs, however the long belt path wont be good in combating acceleration artifacts.

- Cross-Axis/Ultimaker: That could be the one. No moving bed, short belt path and a contained frame, make this a promising option.

With a cross axis design, we would only need one ball screw per axis. With the rigidity we gain from the ball screws we could probably get away with not using a bowden extruder.

That leaves just calculating if we can get cheap enough ball screws and if a normal NEMA17 can drive them fast enough...

This looks pretty much like the design I would go for.