I´ve seen some great bowden extruders which even worked with very good retraction settings, the one on the Eventorbot is not one of them.

The first problem I had with it was that the geared motor did only the backward part of the retraction but failed to push the filament forward again.

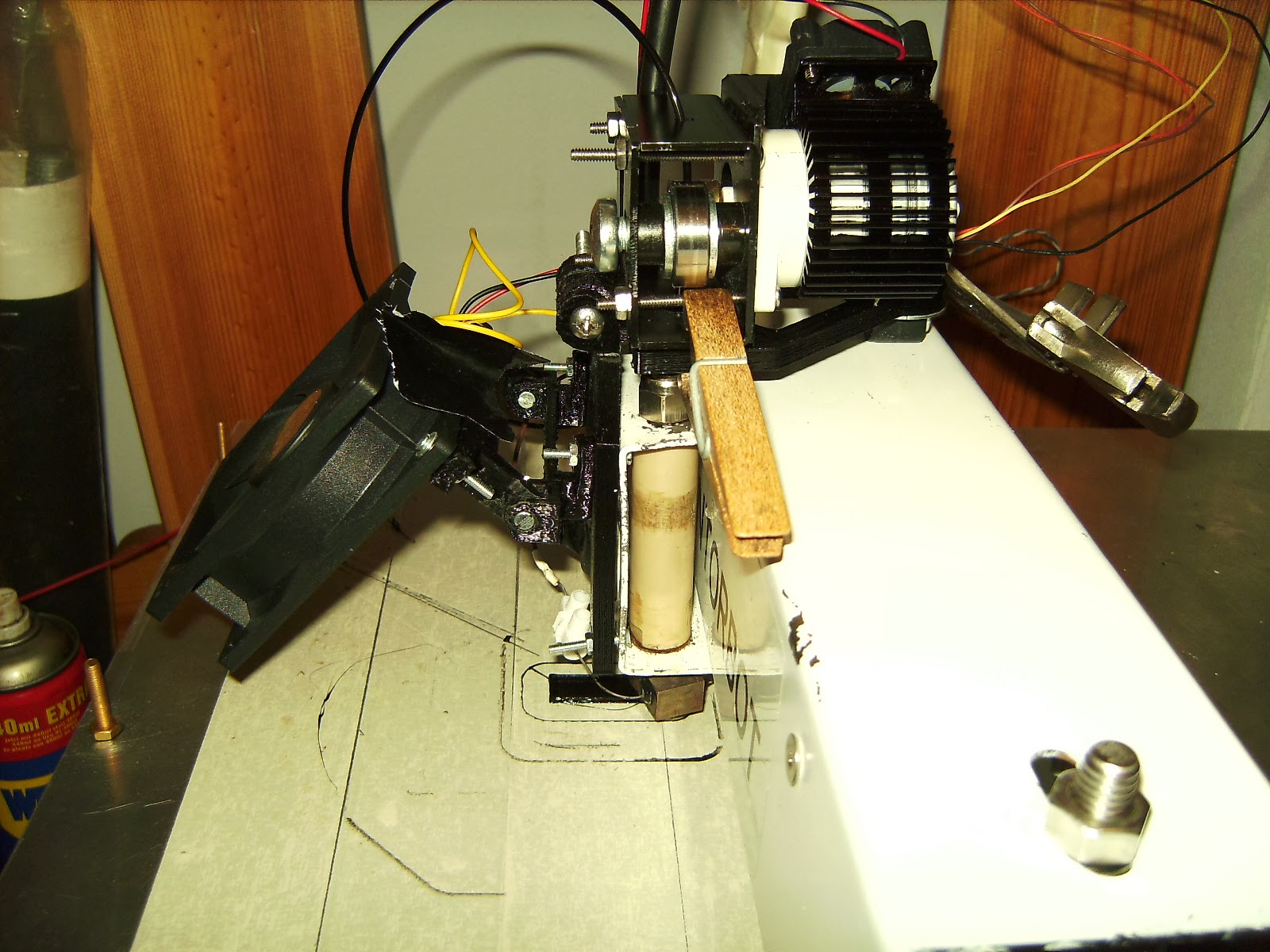

A new NEMA 17 motor solved that problem and even when directly driven without any gear reduction seems to work fine. I still am not convinced about the use of the huge gear reductions the Wade extrudes bring with them but that a topic for another conversation.

|

| The clothpin held down the motor |

I decided rather quickly to go for a direct driven non-bowden design and started with a faceplate which would serve a connector for motor and filament guide. In the

first version my goal was just to mount everything but didn´t pay much attention to the forces that are at play here. The way the motor was connected to the housing would push the motor up rather then push filament down into the nozzle.

In the

2nd version I went for a spring loaded filament guide which directs all force down where it belongs. One issue still even in the rather balaced design is that the clamping pressure is between the housing/filament guide and the motor screws. If that is not well fitted the plastic will give in and filament will just slip.

For the 3rd version I had the idea of putting a cogwheel on the motor shaft and adding a 2nd axis with a 2nd drive gear to hopefully give the filament grip from both sides. The would apply clamping pressure only there where it is directly needed.